DIAMOND CUT

Antwerp diamond cutters

Antwerp is also home to the most renowned diamond cutters in the world. Despite competition from countries with low-cost labour, Antwerp maintains a reputation for quality. Most large stones are cut there: from one carat to… Many Antwerp firms have invested in diamond cutting in Vietnam, India, Thailand and so on. They have had to face problems relating to language, mentality, infrastructure (electricity is often lacking), supplies of all kinds, staff (managers from abroad are often demanding) etc. They must also deal with the ignorance of local authorities including customs and different ministries. To this must also be added shipping and insurance charges. These countries have the disadvantage of “only” being producers of cut diamonds, but not consumers.

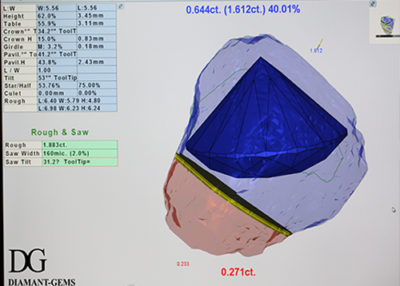

Robots will maybe, and even probably, replace the 20th-century family cutting industry, in favour of sophisticated “laboratories”. However, this will benefit the consumer: cutting will be cheaper and polishing will continue to improve. Rough stones will be analysed by computer, then cut using lasers. The yield of rough diamonds will then be paramount on a scientific basis, taking into account all of the characteristics of the diamond : colour, weight, cut, clarity.

The Size of a Diamond: Cut

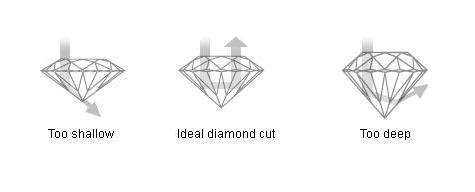

The better a diamond is cut, the more it will reflect light and thus the more shiny it will be. The role of a diamond-cutter is crucial because, even with perfect colour and clarity, a diamond that is badly cut will never be as shiny as it could have been. On the other hand, if a diamond is well-cut, the lustre of a diamond will be increased.

From an uncut to a cut diamond: 4 technical steps of the process

The diamond-cutter begins with a specific test to determine which form to give and the way he will cut in order to obtain the biggest diamond(s) with the least possible impurities.

He then cuts the diamond following these 4 successive steps:

1. Cleavage

In this step the stone is cut. The first cut is made in the stone and a blade is inserted to split the raw diamond. It is at this stage that defects are eliminated, such as inclusions (impurities that have appeared on the diamond during cristallisation).

2. Sawing

A disk-shaped saw will allow for the diamond to be cut into many pieces.

3. Shaping

This gives the stone its round shape. This operation is made possible by the use of another diamond which is scraped against the stone to cut it.

4.Polishing

This creates the small flat surfaces that we call facets, thanks to a disk dipped in oil and diamond powder that is rubbed on the diamond.

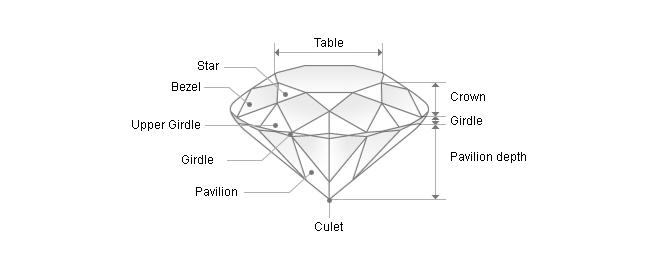

The composition of the final diamond

– The table : it’s the biggest facet of the diamond

– The crown : the upper part of the diamond located above the girdle

– The girdle : the narrow band between the pavillion and the crown

– The pavilion : the lower part of the diamond located beneath the girdle

– The culet : the sharp point of the pavillion

– The chaton: the name of a facet located on the crown of the diamond

– The halefi : a facet located on the crown or the culet

– The star : facette in the shape of a triangle on the crown that separates the two girdles

– The pavillon : facette located on the culet

The brillance of a diamond

You will find diagrams below that simply explain the impact of the size on the lustre of a diamond:

The goal of a diamond-cutter is to cut the stone so that rays of light emanate from the top of the diamond, known as the crown, to maximise its lustre. He will also try to optimise what one calls the proportions of a diamond. The measurement device used for this is called a “Proportion scope”. Beyond these proportions, the cutter also has to have an eye to optimise the finish, that is, the quality of the polish (the finishing of the stone’s exterior) and its symmetry, which has an equally important impact on the lustre of the diamond. You will find an evaluation of these on your certificate :

– Excellent

– Very good

– Good

– Fair

– Poor

Shapes of diamond

There are many ways to cut a diamond and thus many forms a diamond can take:

– Brillant cut

– Princess cut

– Emerald cut

– Asscher cut

– Oval cut

– Radiant cut

– Pear cut

– Heart cut

– Cushion cut

We owe the invention of the “brilliant” cut to Marcel Tolkowsky, who discovered the round form that allows for maximal sparkle of a diamond in 1919. It is the most widespread cut today, with 58 facets.

The Size of a Diamond: Cut

Marking

Once a full examination of each rough diamond has been carried out, the stone is marked to decide how it should be cut to yield the greatest value. At this stage, the shape of the rough diamond and the number and location of imperfections must be considered. The marker or planner must determine the direction of the cleavage (or grain) in the diamond. Due to the diamond’s atomic structure, it can be cleaved in four directions parallel to the octahedron crystal faces.

Cleaving

If the planner decides the stone should be cleaved, it then goes to the cleaver. Large diamonds are often pre-shaped by cleaving into pieces suitable for sawing. For stones that are considerably large and valuable, cleaving is critical as a mistake by the planner or cleaver could shatter the stone. Using another diamond as a cutting tool, a groove is cut along the line showing where the stone is to be cleaved. The cleaver mounts the diamond in a dop, or holder, inserts a steel wedge into the groove and strikes the wedge sharply with a mallet to split the diamond along its cleavage.

Sawing

The third stage (or second if cleaving is unnecessary) is sawing. The specialised saw is a paper-thin disc of phosphor bronze, rotated on a horizontal spindle at about 4,000 revolutions per minute. Mounting the diamond in a dop, the sawyer clamps the diamond so it rests on top of the blade. The rim of the saw is charged with diamond dust, so that as the sawing continues, the blade continues to recharge itself with diamond from the crystal being cut. The saw is able to cut through a 1-carat rough diamond in 4 to 8 hours, but if it hits a knot, the process may take much longer.

Laser Sawing

Today many diamonds are cut using laser equipment which is far more accurate and efficient. The laser saw revolutionised diamond cutting when it was introduced in the 1930s. The stone is mounted onto a dop (similar to those used in conventional sawing) for passage through the powerful laser beam, whilst the progress is monitored on a screen. The burned graphite from the high-temperature laser leaves a black mark around both sides of the stone where the laser cut through. Therefore, these sides then need to be polished. In certain cases, more weight is lost than would have been with conventional sawing.

The biggest advantage of laser cutting is its precision. There is no cutting edge to wear down, and lasers are less likely to warp the diamond because the heat is confined to such a narrow space. Since this method causes less friction on the stone, it is also safer – although temperatures are extremely high. Efficiency is also an advantage, as less manual labour and higher-speed technology means speedier production is possible.

Girdling

The following step is called girdling, and may also be referred to as rounding or bruting. The stone is placed in the chuck of a lathe and as it spins, a second diamond mounted in a dop at the end of a long handle is held against it. This process slowly rounds the diamond into a cone shape.

Faceting

After the diamond has been girdled it is sent to the lapper, or blocker, who specialises in placing the first 18 main facets on a brilliant-cut diamond. Next it is sent to the brillianteer who creates and polishes the remaining 40 facets, when the diamond is being cut in the standard 58-facet brilliant cut. For placing and polishing, the stone is set either in a lead dop or a mechanical clamp and held down on a revolving cast-iron lap (a horizontal, circular disc) that has been charged with diamond dust. Extra care is required at the faceting stage because the angles of the facets must be exact in order to yield maximum brilliancy, and their sizes must be accurately regulated to preserve symmetry.

Finishing

Once the fully faceted diamond has been inspected and approved, it is then boiled in hydrochloric and sulphuric acids to remove any dust and oil. It is then considered a finished, polished diamond. Such loose diamonds are then ready to be distributed to wholesalers, manufacturers and retailers to create products for the diamond shopping consumer.